Traditional Wood or Fiberglass: What is the best option for replenishing boats lost to Yolanda?

A question that is starting to take shape as we begin replacing fishing boats in Samar and Leyte that were lost to Typhoon Yolanda (Haiyan) is — does it make more sense to replace the boats locally, with motorized bancas constructed locally in the traditional way, or replace them with fiberglass motorized bancas which, unless something changes, would be produced outside the storm zone and trucked in after completion.

For the sake of discussion and analysis, let’s assume that the bottom line price is the same — P25,000 for either option — but the fiberglass boats would be built in Manila and delivered to Samar, while the wooden boats would be built locally in Samar.

Fiberglass Bancas at a Factory in Bulacan, Near Manila

Analysis

I have to admit that the idea of fiberglass bancas is intriguing. They are eco-friendly, they last longer — and going that route conforms to the “build back better” dictum which is mantra for best practices in post-disaster rehabilitation.

But there is a counterargument that favors rebuilding the fleet traditionally on site in Samar.

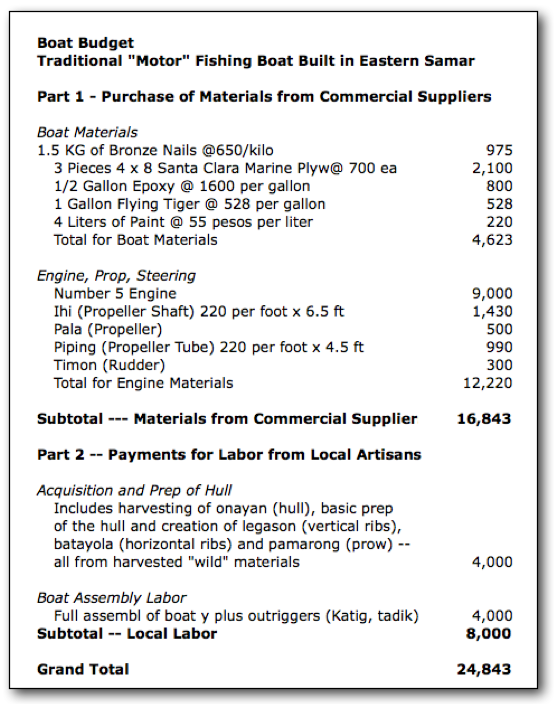

The counterargument goes as follows. Although the price is P25,000 for each, the locally built native boat includes, within the cost of P25,000, about P8,000 that will go to local artisan boat builders for their labor contribution to the boat that is created. Here is a breakdown of the budget for a boat, dividing it into supplies purchased from stores/commercial outlets (currently in Catbalogan, which is a little bit outside of the main affected area, but soon perhaps these purchases could be made in Guiuan, which is within the affected area and thus the purchases in Guiuan stores would directly benefit the affected region)

The question is this: Is the payment of P8,000 in local labor costs a big enough benefit to offset the benefits of fiberglass?

How do we measure the benefit?

First, there is the actual P8,000 paid.

Artisan boat builder working on the onayan (hull) and legason (vertical rib) assemby of a traditional fishing boat.

But we also have to consider the full “life cycle” of that P8,000. What happens to it and how does that affect the community> This is normally thought of as the “multiplier effect”. The P8,000 goes to two different parties — first, P4,000 goes to the person or family who gets the contract to go into the forest and “harvest” the onayan (hull) — a process that is largely labor except for the cost of food for the team doing the work. (A chain saw rental is a cost if a chain saw is used, which is optional.) Typically the same person or team that obtains the onayan, then also creats and provides the legason (vertical ribs), batayola (horizontal ribs), and pamarong (prow) — then delivers the hull, legason, batayola, and pamarong as a complete kit for P4,000. The reason this is counted as labor is that the materials are all “harvested” — not purchased. (I am not sure what the legality of this is but it’s the traditional way of doing it.)

The second P4,000 goes to the artisan boat-builder who takes the onayan kit and all of the other boatbuilding materials and puts the boat together to completion.

What do these two parties do with the money?

Generally, they spend it in the community for food and other necessities, paying it to others who in turn also spend a portion of it in the community.

In this way, so the theory goes, the P8,000 paid for local laboar actually has an economic impact within the community of somewhere between 16,000 and 24,000 pesos of economic activity/transfer that would have not happened otherwise.

Does this additional economic benefit rise to the level of something that justifies going the traditional route, rather than fiberglass?

Creating a Local Fiberglass Manufacturing Capability

The longer term option that seems attractive would be to create a local fiberglass boat-building capability in Samar. That would allow the best of both approaches — there would be local labor payments that would stimulate the local economy, plus the fishermen would get a fiberglass banca that lasts 15-20 years.

From what I can tell based upon the reading that I’ve done and videos I’ve watched — the investment required to create a fiberglass boat building capability in Samar would be quite small, and the market is apparently quite huge. How much, exactly? I don’t know yet but I’m looking into it.

Stay tuned …. ( and I welcome troubleshooting/debugging of the arguments either here or on Facebook).

Year of the Spy Book Trailer

Above is the Year of the Spy Book Trailer — for my upcoming non-fiction book about espionage upheavals on the streets of Moscow in 1985.

Below is a “trailer” showcasing the writing and video services I provide to clients.

Michael Sellers — Writing and Video Services

My eBook — Just released Dec 5, 2012

EBook You don't need a Kindle or iPad -- Download Adobe Digital Editions for Free, then read the .mobi (Kindle Format) or .epub (Nook, iPad Format) digital book on your computer. Or order the PDF which is formatted exactly like the print book.Recent Posts

- Arsha Sellers — Today I’m One Big Step Closer to Becoming a Real Forever Dad

- Meet Abby Sellers and Arshavin Sellers — My Wife, My Son, My Inspiration Every Day

- What the Mueller Report Actually Says

- Remembering James Blount, an American Who “Got” the Philippines in 1901

- America the Beautiful? You Mean America the Pitiful. I Am Ashamed